After following various restos on here over the years, Jon of doom, Alex b, Last triumph, Danregs etc, I have bitten the bullet and made a start on the third, count them, resto on my 69 bug...... only this time I want to do it properly!

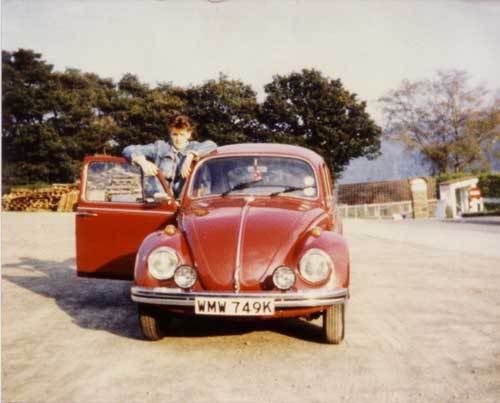

Here it is.........

![Image]()

This shot was taken at bugfreeze 05.

Here it is.........

This shot was taken at bugfreeze 05.